SUBSCRIBE TO THE NEWSLETTER

Receive updates about our latest products, application reports and white papers - right in your e-mail inbox!

Starting situation

For a reliable production process, pressing tools are equipped with various sensors.

Sheet metal position sensors, for example, check before the stroke, whether the part from the previous Operation stage is correctly inserted and thus secures, that the process of the corresponding operation stage is safe.

To improve process reliability, a production tool had to be equipped with a new sensor characterized by improved properties

Challenges & Procedure

In this application, the necessary pocket-shaped geometry and the holes for the installation of the sensor had to be carried out between two dates for two pressings. A realization with a conventional process would have included the transport of the tool to a large milling machine and relatively long set-up times and, due to the lead time, would have led to a failure of a planned date of a pressing and thus to a significant production loss.

The realization of the necessary geometry was carried out with the Picum processing machine successful in one work shift.

Advantages

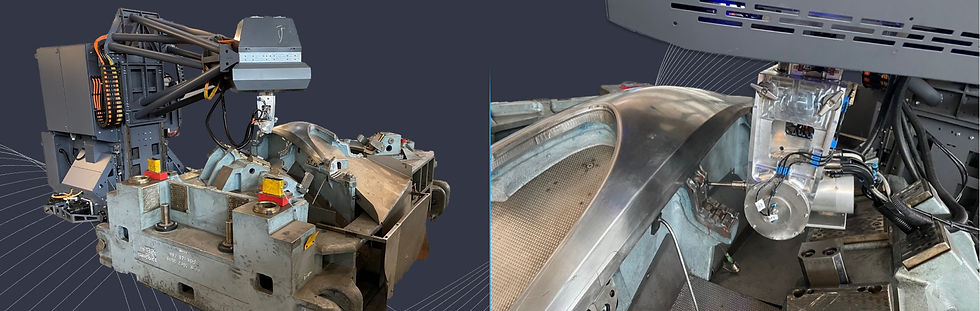

The tool optimization could thus be achieved between two dates for pressing. The pictures on the top show a Picum machine while machining of the corresponding geometry.

The pictures illustrate the flexibility of the processing machine related to the working area: The additional height axis (Z2) for pre-adjustment to the pressing tool stands on a high adjustment position to match the height of the pressing tool.

The picture at the bottom illustrates the setting area of the machine in terms of height. At the same time, the A-axis with the milling spindle is almost horizontal to mill the pocket geometry. The framework of the machine also allows the realization of machining in the center of the pressing tool.

It often shows up when machining with the Picum machine, that, due to the small crash contour of the turn-pivot-head, machining is possible where very large tool machines with very large turn-pivot-heads have problems regarding collisions.

%20Nr%20002.jpg)

%20Nr%20001.jpg)

%20Nr%20004.jpg)

%20Nr%20003.jpg)